Types of Finishes (printed/ coated/ slit)

Dimensions (thickness from 6.5 µm to 440 µm, drop width up to 1,220 mm)

|

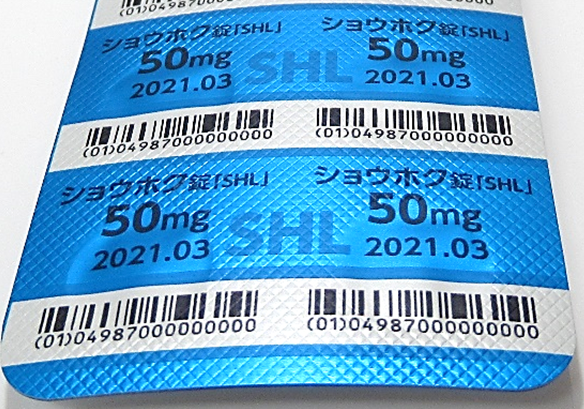

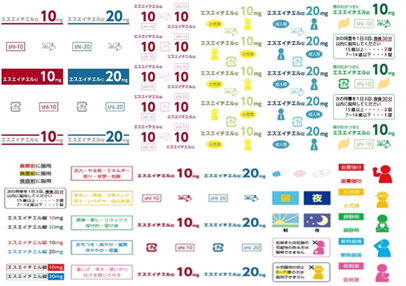

PTP aluminum film

SHL supplies a wide variety of safe and hygienic packaging solutions for products ranging from medicinal and pharmaceutical items to medicine kits and health foods. |

||||||

|

*Gloss Non-coat (R) (Patent No. 5496133)

Gloss Non-coat is a unique coating created by SHL that can be used to generate barcodes (GS1/Databar) that do not require a white background.

*1 Joint exhibition with NIPRO CORPORATION (Forgery prevention PTP sheet) |

||||||

|

* "Shadow" printing (New type of Gloss Non-coat (R), Released in April 2021)

"Shadow" printing applys our long-selling product "Gloss Non-coat (R)" technology. |

||||||

|

*Functional PTP (R) (Patent No. 5941194)

Functional PTP is a PTP sheet that contains a functional aluminum layer. |

||||||

|

*Flexible PTP(patent pending)

Flexible PTP is a stretchable form of PTP aluminum foil made with a special coating. |

||||||

|

*Low-formaldehyde PTP

Unlike conventional PTP packaging materials, low-formaldehyde PTP emits close to zero formaldehyde when heated during the packaging process. |

||||||

|

*Stealth Type Printed PTP (UV Light) (patent pending)

A continuous post-printing system is used to add both visible and invisible text. Suitable for small-lot production runs. |

||||||

|

*On-demand Printed PTP (Inkjet Form) (patent pending)

On-demand printing enables full-color printing without printing plates, opening up a whole new world of color and design options for PTP packaging. |

||||||

|

Laminated Film

SHL supplies an extensive range of laminated film packaging materials for medicinal and food products including pillow film, folded film, SP packaging, digitally printed pillows, pharmaceutical sample bags, shrink film, overlap, sterilized packaging, plastic canisters, aluminum tubing and polyethylene bags. |

||||||

|

PTP Container Film

PVC sheeting, polypropylene sheeting and AL/AL packaging. |

||||||

|

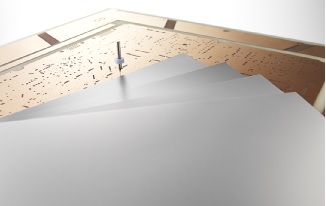

Custom Entry Sheet for PCB Processing (multiple patents)

Custom entry sheet helps to reduce friction on drill bits when drilling into the substrate. It also improves dimensional accuracy, produces smoother internal walls on drilled holes, and reduces the incidence of snapped drill bits. |

||||||

|

Carbon-coated foil for batteries

We make carbon-coated aluminum foil products, drawing on over 40 years of experience and knowledge with aluminum foil production and quality control systems. New production equipment coming in FY2020 will boost production capacity and can accommodate substrate widths of up to 1.2 m. It will also enable production of custom lines such as carbon-coated copper foil and carbon-coated foil combined with client-supplied electrode coating in accordance with ever-changing needs. |

Contact us csm@shohoku.co.jp